In 1820, Hans Christian Ørsted conducted an experiment that redefined the worlds of both science and engineering. Upon passing a current through a wire suspended above a compass and observing the compass needle move, Ørsted was able to conclude that the electric and magnetic forces – both recognized as separate forces – were indeed related, and thus, unified. This observation was further expanded on by James Maxwell, who later asserted that changing electric currents can produce electromagnetic fields, thus establishing the existence of electromagnets. Since then, electromagnets have become the keystone to technological advancements that have contributed to the development of MRI devices in medicine, electrical circuitry used in numerous electrical applications, and maglev trains in transportation.

Since 1984, numerous countries worldwide have utilized maglev trains to transport people across large distances, the first of which being located in Great Britain. The most famous maglev train in the world, however, is the Shanghai Maglev, which connects the Pudong International Airport to various neighborhoods in Shanghai’s Pudong district. The train is able to reach record speeds of up to 501 km/h (301.3 mi/h) and was able to transport a record number of 53 million passengers in 2023.

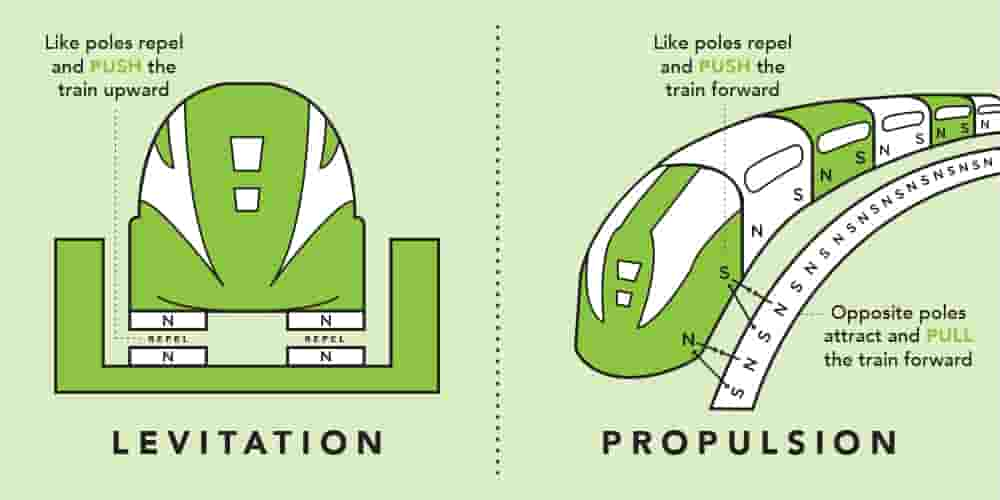

While there are three primary types of maglev operating systems, most operate using a rudimentary principle that is discussed in the majority of high school science classes: principles of magnetic attraction and repulsion, though on a much larger scale. For example, the most common mechanism used on maglev trains utilizes cars that have four magnets on the bottom corners. The magnets beneath the train car have opposing poles to the ones on the bottom of the track; when electricity runs through these magnets, the trains begin to levitate. Moving trains forward requires another set of electromagnets. Electromagnets on the sides of the tracks are placed so that their poles alternate with respect to the ones on the train car, (ie.alternating between north and south), and therefore, pulling it forward using attractive and repulsive magnetic fields. While levitation helps the train gain speed, guide wheels are often used for stability, and ensure that the train remains on the tracks.

As the train accelerates, its levitation increases. Several trains can levitate up to 4 inches (10 mm) above train tracks at high speeds, which also serves to considerably reduce the amount of friction acting upon the train. This allows maglev trains to reach significantly higher speeds than their diesel or rail counterparts. While they still experience some friction from air resistance, there is less energy lost to heat and sound, which are common characteristics of traditional rail trains. Ultimately, as the majority of their energy is directed towards propelling the train forward and allowing them to reach higher speeds, maglev trains are praised for being an energy-efficient alternative to traditional trains.

Due to the fact that maglev trains employ the use of electricity, as opposed to fossil fuels as an energy source, they also produce fewer carbon emissions, making them a “greener” source of transportation that reduces traffic congestion in urban areas. According to Sayeed Mavani from the McGill Business Review, plans to develop a high-speed maglev rail system in the northeastern United States will connect various neighborhoods across northeastern states, while indirectly helping “reduce current rail energy consumption by 30 percent.” This project is also projected to increase the US Gross Domestic Product (GDP) by approximately “$254 million annually,” demonstrating that maglev trains have the potential to substantially boost the economy. While initial funding to build maglev systems from scratch may be expensive, the long term benefits offered are too great to ignore. As a highly efficient machine displaying a wide array of consistently positive benefits, maglev trains are a low energy, highly efficient method of transportation that should be implemented on a global scale to reduce carbon emissions.

Works Cited

- BYJU’S. “Uses of Electromagnet with Its Applications in the Practical World.” BYJUS, 2023, byjus.com/physics/uses-of-electromagnet/. Accessed 27 August 2024.

- “China: Number of Passengers on the Beijing-Shanghai High Speed Rail Line 2023 | Statista.” Statista, Statista, 2023, www.statista.com/statistics/1074379/china-number-of-passengers-transported-on-beijing-shanghai-high-speed-rail-line/. Accessed 28 Aug. 2024.

- Li, Shiyi. “State of the Art and Future Development of Magnetic Levitation Technology.” Highlights in Science, Engineering and Technology, vol. 31, School of Electrical and Electronic Engineering, North China Electric Power University, Baoding, China, 2023. Accessed 26 August 2024.

- Mavani, Sayeed. “Travelling Green: Is Maglev the Future of Eco-Friendly Transportation?” McGill Business Review, McGill Business Review, 23 August 2021, mcgillbusinessreview.com/articles/travelling-green-is-maglev-the-future-of-eco-friendly-transportation-1. Accessed 25 Aug. 2024.

- Mitchell, Alanna. The Spinning Magnet. Penguin Random House, 2018. Accessed 22 August 2024.

- Whyte, Chelsea. “How Maglev Works.” Energy.gov, US Department of Energy, 14 June 2016, www.energy.gov/articles/how-maglev-works. Accessed 27 August 2024.